Open single crankshaft precision punch

Open Double crankshaft precision punch

Semi-closed single crankshaft precision punch

Close single-crankshaft precision punch

Closed double point crankshaft precision punch

Close double-crankshaft precision punch

Open single point servo model

Gantry dual point servo model

Special machine for open double crankshaft battery shell

Closed single point high speed punch

Three post guides high-speed precision punch

Gant Type Speed Precision Four Post Guider Press Machine

Straight Column Type Four-points ecdenttric press machine

Split and close double-crankshaft precision press machine

- Tel: 400 100 5226

- Fax: 0510-68392919

- E-mail: sherry@yisto-east.com

- Address: No.422, Xizhang Road, Gushan Town, Jiangyin, Wuxi, China

Straight Column Type Four-points ecdenttric press machine

Release date: 2024-08-15 15:00:27 Visits: 89

● High precision stability and reliability

● Net (near) forming precision forging equipment,Toggle mechanism, bottom dead center position have certain pressure holding characteristics,Connecting rod mechanism, can expand the stroke and nominal force stroke, High rigidity frame and eight side guide rail, increase the ability of antieccentric load of the press, ensure the high precision of the press,With the knock out device, realize the perfect cooperation between the press and the automation device.

Performance feature

● Implementation of high density machining

● Low noise implementation

● Realization of convenient operation

● The die height variation is small and the kinetic Center deviation is small.

● Die life greatly improved

● Small deformation of stamping.

● Cutting noise is small.

● Low general clearance

● The servo motor is adjusted to improve the convenience and accuracy of mold adjustment.

Standard configuration

|

● Electric automatic lubricating device ● Electric slide adjusting device ● Electric die height indicator ● I slide and die balancing device ● Electronic cam control display ● Read from the brake performance monitoring device ● Static SPM display function ● Repair instructions function ● The air source socket ● Air blowing device ● Two degree drop protection device |

● Detecting device ● Main motor reversal device ● Electronic trip counter ● Pre cut counter ● Preset counter ● Power socket ● Independent control box ● Operating platform ● Base plate and the bolt ● Maintenance tool box ● Operating instructions |

Optional configuration

|

● Pneumatic die cushion lifting device ● A photoelectric safety device ● Knock-out device ● I die lighting device ● I know death under inspection ● The pedal operation switch |

● Flywheel brake device ● Safety block bolt ● Moving table ● lift the mold,clamps the mold or die arm ● Automatic feeding system ● Lsolation mounts |

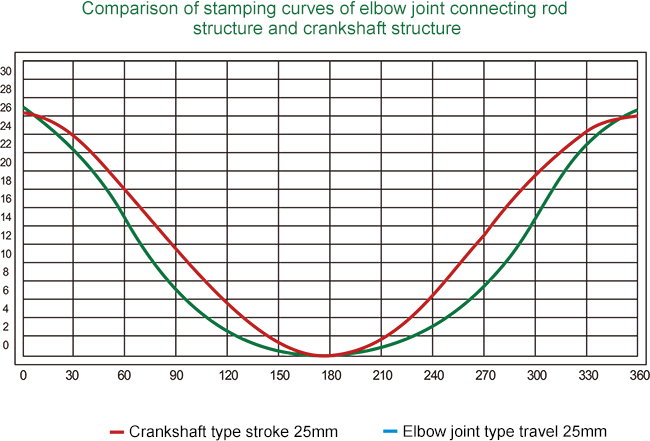

● Our MISk Super series press is seeking higher productivity under the features of knuckle mechanism with simplicity and optimum . This new knuckle press machines has a simple design and high rigidity for such components as lead frames, connectors, terminals, motor cores etc.

● Symmetrical knuckle mechanism has been proven to perform high speed fine precision stamping owing to minimal of thermal displacement breakthrough and stability.

● The advantage of knuckle mechanism is designed for rigidity and thermal balance in addition to simple structure.

● Balance mechanism which countervails left and right components of force, and double slide-guiding system which iscomposed of 2 Plunger and 8 faces needle bearings, elevate the capacity of eccentric load-resistant.

|

JIS superfine precision--good rigidity and high precision

The slider is guided by a guide of double plungers and octahedral flat roller with nearly no clearance in it has goodrigidity, high inclined loading resistance capability,and high punch press precision High Impact-resisting and wear-resisting property of the guide materials guarantee long-term stability of the punching machine precision and prolong the intervals of repairing mould.

|