Open single crankshaft precision punch

Open Double crankshaft precision punch

Semi-closed single crankshaft precision punch

Close single-crankshaft precision punch

Closed double point crankshaft precision punch

Close double-crankshaft precision punch

Open single point servo model

Gantry dual point servo model

Special machine for open double crankshaft battery shell

Closed single point high speed punch

Three post guides high-speed precision punch

Gant Type Speed Precision Four Post Guider Press Machine

Straight Column Type Four-points ecdenttric press machine

Split and close double-crankshaft precision press machine

- Tel: 400 100 5226

- Fax: 0510-68392919

- E-mail: sherry@yisto-east.com

- Address: No.422, Xizhang Road, Gushan Town, Jiangyin, Wuxi, China

Open single crankshaft precision punch

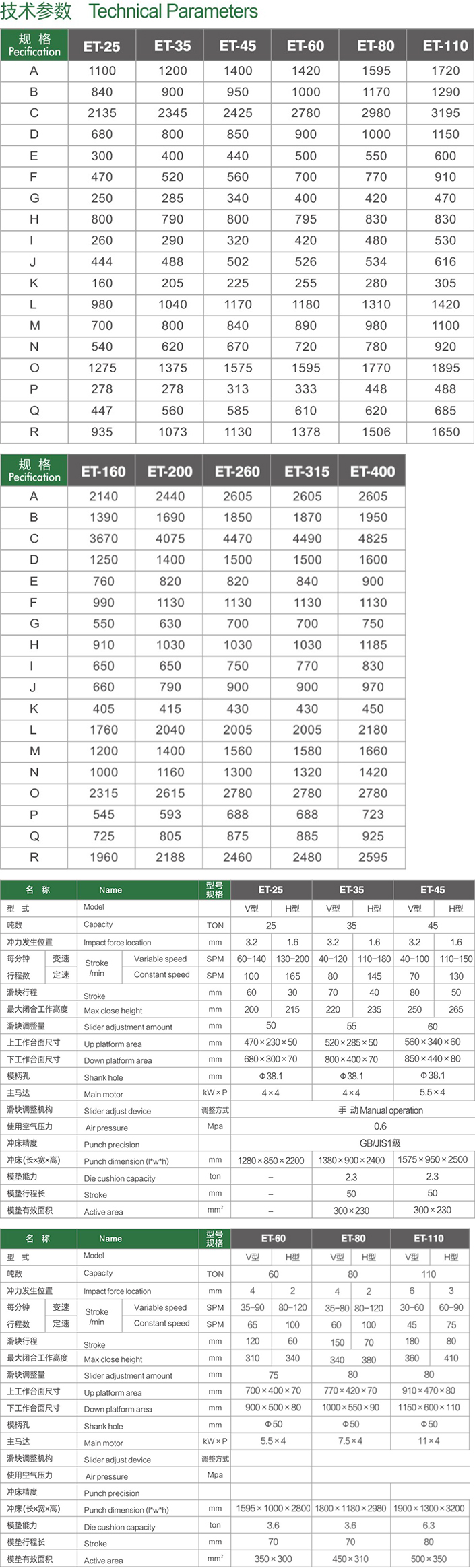

Release date: 2024-08-15 11:31:27 Visits: 128

● With high rigidity rack design, they are welded with theuse of high-quality steel plates, through relieving ofinternal stresses, so that stability and reliability of the whole machine in precision are enhanced.

● Consistent driving center and machine center toguarantee accurate and stable punching.

● Moulding-adjustment precision is as high as 0.01mm, safe, speedy,and reliable.

Performance feature

● In order to guarantee relative stationarity of machine operation, it isnecessary to balance two balancers.

● Through hard oxidation and grinding, such parts as bent axles, gear sets,and connecting rods possess higher combination property and tolerance.

● Adopt highly sensitive and reliable clutch/brake and internationallytop duplex magnetic valve, as well as overload protection devices, toguarantee precision and safety for operation and stop of press rams.

● Machine''''''''''''''''s structural design shall be reasonable, for the convenience ofrealizing automatic production, reducing cost, and improving efficiency.

● Possess advanced design concepts,low noise,low consumption, and energy saving.

Standard configuration

|

● Oil-pressure overload protection device ● HM slider adjusting device(≤ ET60) ● Electrodynamic-typeSlideradjusting device(≥ ET80) ● Frequency-conversion variable speed motor(speed controlled) ● Mechanical height indicator(≤ ET60) ● Digital height indicator(≥ET80) ● Slider and mold balancing device ● Electronic cam switch device ● Crankshaft angle indicator ● Electromagnetic-type counter ● Air source contact |

● Second falling protector ● Air blowing device ● Mechanical quakeproof foot ● Miss inspection device ● Maintenance tools and tool cabinet ● Main motor inversion set ● Photoelectricity safety protection device ● Power socket ● Electrodynamic-type butter lubricating device(≥ET80) ● Touch screen(prejudge and preload) |

Optional configuration

|

● Induction hardening of slider guide ● Precision grinding ● Vapor-pressure-typediebacker device ● Foot switch ● Quick exchange of die device (die lifter, die clamper or die mover) |

● Top of slider material device ● Feeder (air, machine and NC) ● Bump-cutter machine ● Mechanical arm ● Die lighting device ● Material frame ● Thin oil lubricating device |

Previous: Open single crankshaft precision punch

Next: No